|

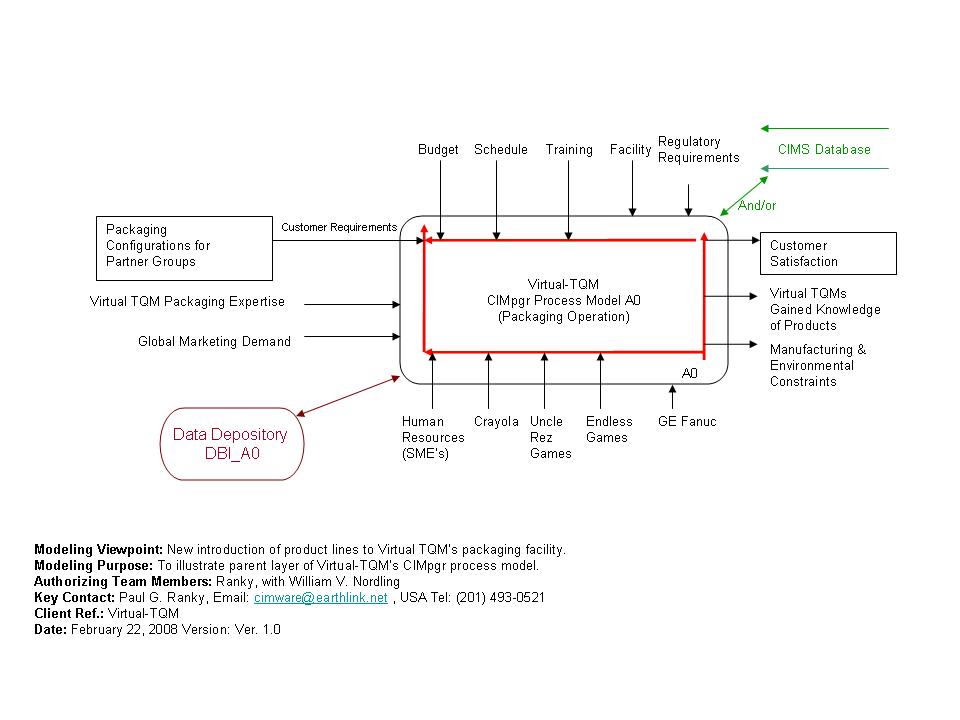

First Layer of Process Model (A0)

By observation we can see that customer requirments will be driven by the packaging configurations of their

respective product and ranks highest on the priority gauge. To a lesser extent will be in house expertise. The

packaging lines are highly automate and have the latest inspection systems which will ensure that quality product is introduced

to the market. Data will be collected as various prodcuts are introduced and knowledge is gained. This data will

enhance Virtual TQM's understanding of the packaging configurations allowing us to streamline processes and reduce changeover

time if like line set up will be utilized for similar packaging configurations. The ultimate goal with the highest priority

of course is customer/client satisfaction.

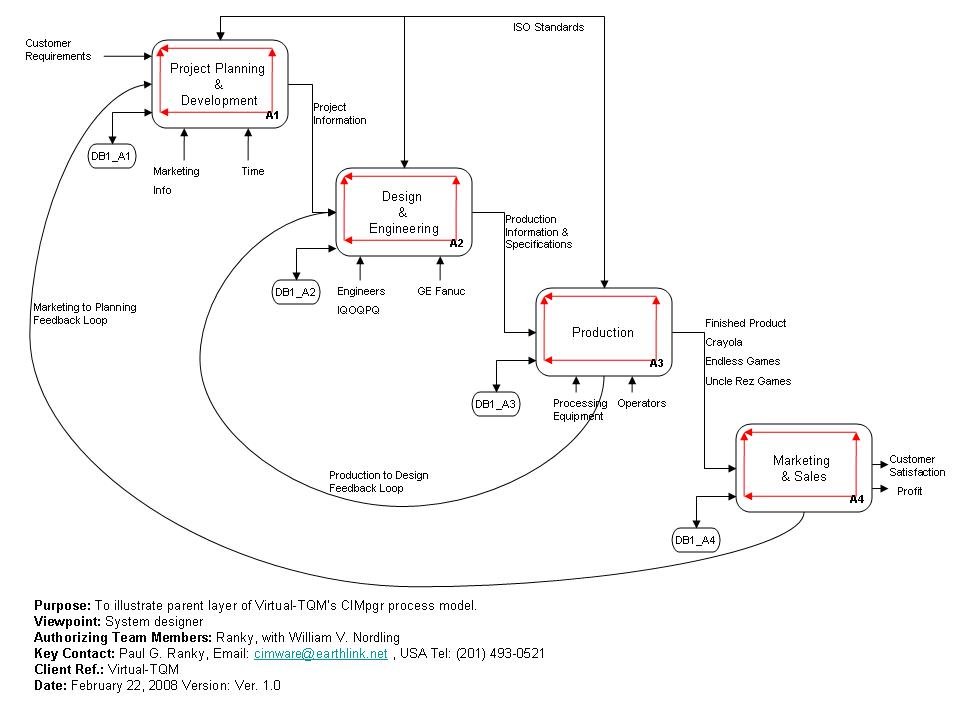

Second Layer of Process Model (A1, A2, A3, A4)

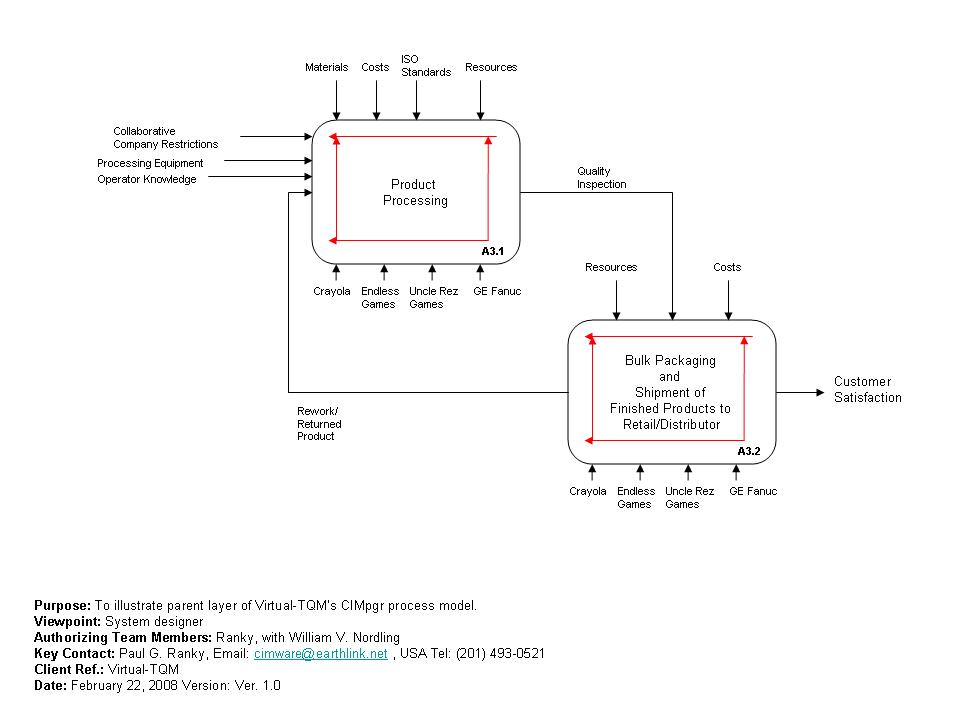

Third Layer of Process Model (A3.1, A3.2)

CASE VIDEO FILE

ANALYSIS:

As part of this exercise, two full length

video files were viewed to determine how each company approaches their respective quality assessment. The following contains a

summary of each companies approach to the quality assessments.

Bentley Quality:

Bentley

specializes in automobiles with an high degree of quality and craftsmanship built into there designs. Bentley’s goal, or the “Essence of Bentley” is to deliver a car that portrays style &

design, power & performance and a high degree of cache & sex appeal. These

attributes aren’t necessarily needed for the car to operate correctly yet is incorporated into the design base on customer

feedback and wants. The company maintains a customer base by designing cars that

are extremely pricey due to the quality that is built into them. Most purchasers

of a Bentley are selfmade and purchase the car as a means to flaunt their financial status and success. Bentley acknowledges this and therefore designs there automobiles with customer satisfaction

in mind. Bentley uses materials that the purchaser associates with a quality product and the construction shows a high

degree of craftsmanship. They utilize materials such as wood, leather and metal

to accomplish this. They construct their automobiles with extreme detail and ensure that each automobile is pieced

together with tight tolerances. To a purchaser, they want to see this high level

of detail that comes with the high price tag. They incoporate all standard safety features along with more modern conveniences

such as GPS and elaborate sound systems. All this is tied into a classic yet

timeless look and feel. As previously

mentioned Bentley relishes in the detail and level of their craftsmanship and is unmatched in their eyes. Skilled fabricators are trained to perform the assembly of each automobile with each having years

of experience. From the instrumentation panels to the hand stiched seats the

level quality is superb and shows no variability. The tolerances and marriage

of parts ensure that the appearance showcases a quality product. Comfort and control is also a major part

of each of the automobiles. A large wheel

base ensures adequate space is provided to the driver as well as passengers. The

enlarged rear seating also targets the passengers and allows them to enjoy the overall quality of the cars design as well. Bentley is regarded as the upper echelon in the automobile industry and rely

on their customer base to dictate the level of quality built into their product. They

educate and recruit the best up and coming designers. Younger designers from

around the world bring their contemporary influence to interject new and creative ideas, thus enabling the company to keep

up with the latest innovations.

COGNEX-VISION:

Cognex

vision systems are primarily for the inspection of product for defects. This

is an online system that can be used with continuous production lines. The systems

are multifunctional in that can be used for dimensional gauging, defect inspection, robot guidance and identification. The dimensional gauging capabilities of the systems can be used for measuring distances

and/or tolerances with respect to reference points. It can read edges by viewing

contrasting patterns and thus define shapes. Defective parts can be identified

by programming the system prior to inspection with the correct acceptance criteria. The systems can also be used for

robot guidance for variables such as positioning, angle, scale and variation. Products

can be marked with code for identification puroposes. A 2D data matrix code can

yield information such as type of part and date of manufacture. The systems can also generate statistically data

from measurements. The data can be analyzed online and spot trends that can identify potential trends that might result

in an out of control system. The system is internet based allowing for viewing from various locations. While the

product pass by the vision system it takes a static image with scan time being dependant on line speed and complexity of the

item being scanned. The vision system is much more efficient in identifying components that do not meet specifications.

All of the attributes of the Cognex vision system ensure that a quality product is being shipped to the consumer by elminating

the potential for defective product making its way to market.

SUMMARY:

Utilizing

the CIMpgr approach, one can identify the resources needed to see the

product through its lifecycle. By defining the variables associated with the

production of end product, key activities and responsibilities can be identified and monitored towards improvement. The TQM process model will aid in addressing problematic areas that warrant correction.

FURTHER

WORK NEEDED/PROPOSED:

Virtual-TQM will continue to build

upon the foundation of Total Quality Management outlined herein.

REFERENCES:

Enter supporting content here

IE673-852 TOTAL QUALITY MANAGEMENT

|